Back Home

Our Industrial Projects

We specialize in installation, upgrades, and maintenance of industrial machinery across multiple sectors.

Installation of state-of-the-art industrial machinery

We have successfully completed the installation of state-of-the-art industrial machinery . This project covered the entire scope of work — from site preparation and safe delivery to precise assembly, rigorous testing, and final commissioning. The newly installed equipment is designed to boost production capacity, improve operational efficiency, and maintain the highest standards of tea processing and packaging. Our team ensured that all systems were fully integrated and ready for seamless operation, supporting Lipton's commitment to delivering premium quality teas to its customers.

Boiler Service facility

At our Boiler Service facility, we specialize in the maintenance, inspection, repair, and optimization of steam-generating machines—critical components in a wide range of industrial and commercial operations. Our service ensures the reliable and efficient performance of boilers, reducing downtime, enhancing energy efficiency, and extending equipment lifespan.

Machinery Installation and Commissioning service

Our Machinery Installation and Commissioning service for animal feed processing equipment ensures that your production line is installed correctly, tested thoroughly, and fully operational from the start. We specialize in the setup of complete animal feed plants, including machinery for mixing, grinding, pelleting, cooling, screening, bagging, and conveying.

Factory design

factory design , machinery procurement( purchasing them process), installation and commissioning, electrical installation.

Tea Sorting Machinery Installation

Our Tea Sorting Machinery Installation service is designed to ensure the seamless setup and commissioning of advanced equipment used in the processing and grading of tea leaves. We specialize in the installation of both manual and automated sorting systems, including color sorters, vibrating sieves, fiber extractors, and density separators, which are essential for maintaining quality and consistency in tea production.

steam pipe insulation and the installation

We successfully executed a specialized project involving steam pipe insulation and the installation of CFU (Continuous Fluidized Unit) fluidization ducting, aimed at enhancing thermal efficiency, energy conservation, and process stability in an industrial setting.

Lightning Arrestors

Our Lightning Arrestors – Inspection and Corrections service ensures that your facility's surge protection systems are fully functional, safe, and compliant with applicable electrical standards. Lightning arrestors play a critical role in protecting buildings, equipment, and electrical infrastructure from the devastating effects of lightning strikes and voltage surges. Regular inspection and timely correction are essential to maintain their effectiveness.

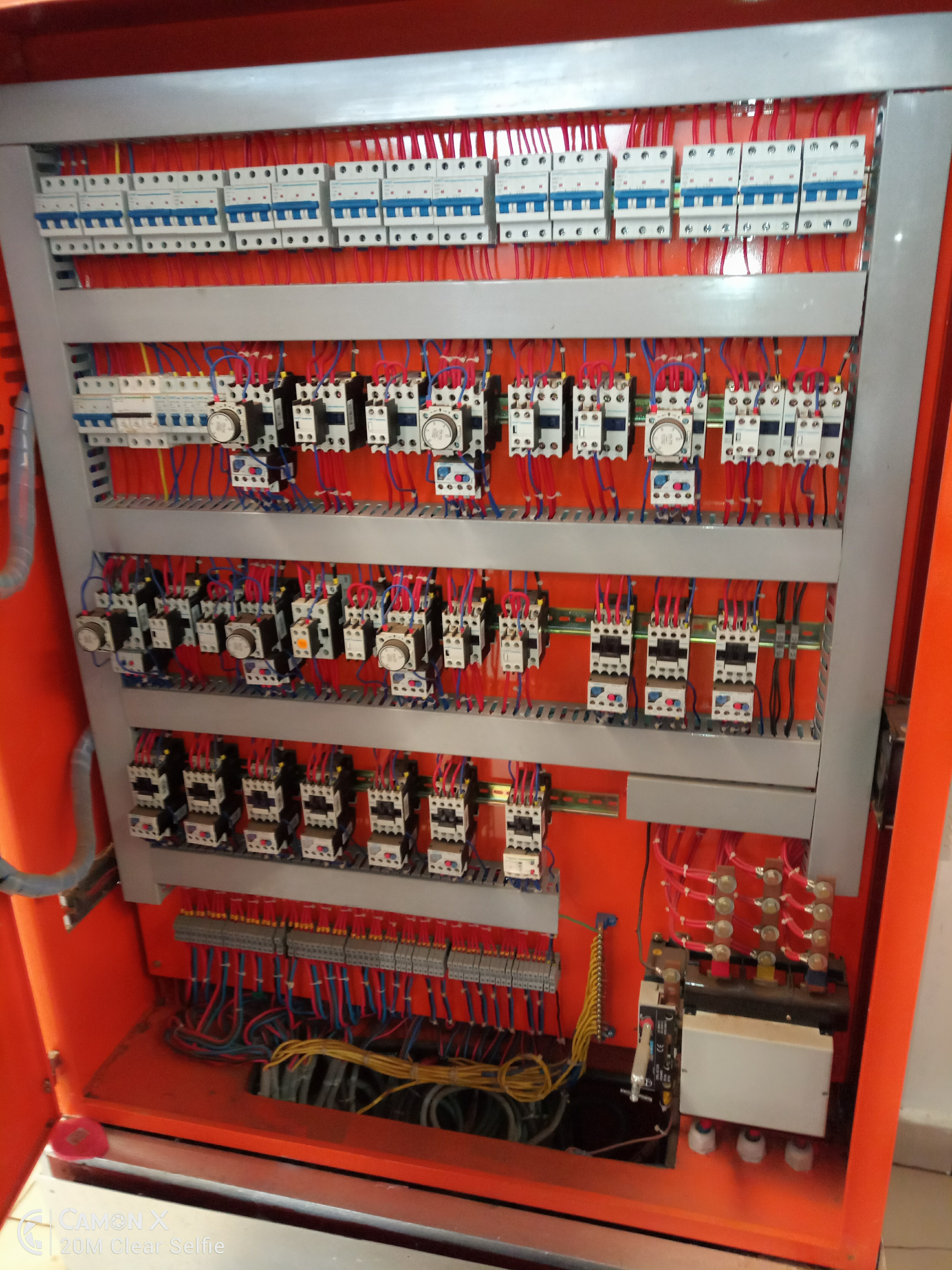

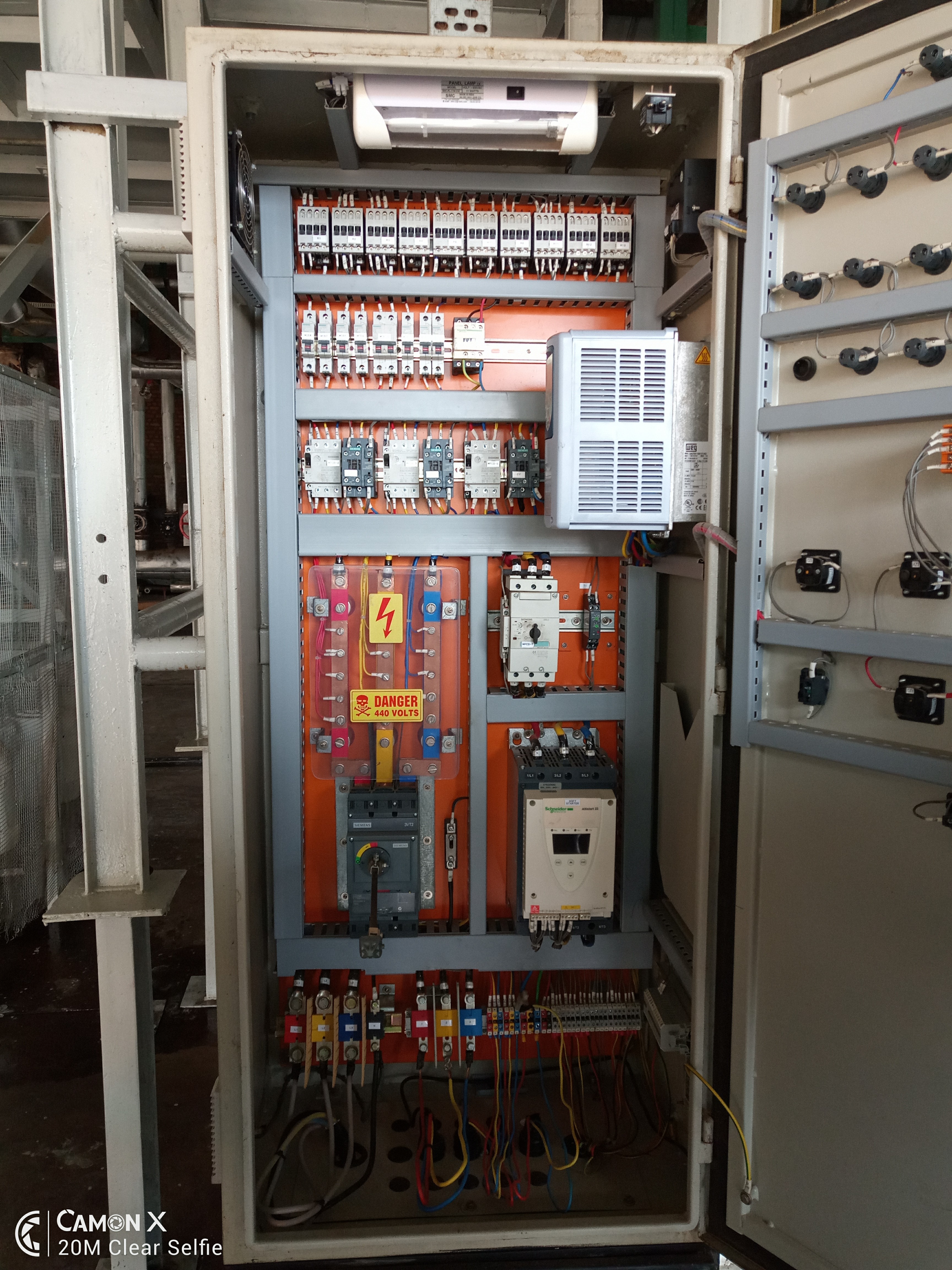

Maize floor processing machinery installation

Maize floor processing machinery installation and commissioning, electrical installationOur Maize Flour Processing Machinery Installation and Commissioning service delivers end-to-end solutions for setting up efficient and reliable maize milling operations. From mechanical setup to full electrical integration, we ensure that your maize flour processing equipment is installed, tested, and commissioned to meet performance, safety, and productivity standards.

Comprehensive infrastructure upgrade

We successfully executed a comprehensive infrastructure upgrade project involving the extension of an existing warehouse facility along with complete electrical system integration. The scope of work began with the structural expansion of the warehouse to increase storage capacity and improve operational flow. This included civil works, roofing, lighting provisions, and layout adjustments to support the extended operations.

Installation of withering

This project involves the installation of withering troughs—specialized equipment used in tea processing for the withering stage, where freshly plucked tea leaves are laid out to reduce moisture content and enhance flavor. The installation includes mechanical setup, alignment, and structural support to ensure efficient airflow and leaf handling.

All projects showcased on this page. Scroll for more.